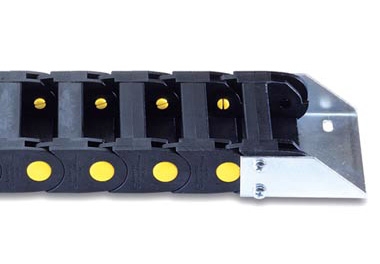

Nylon cable chain SR305

Xích nhựa dẫn cáp series 305

Là loại xích dẫn cáp cỡ vừa dễ dàng và linh hoạt lắp đặt kết hợp chắc chắn – sự ổn định cao kết hợp với vận hành êm, thời gian phục vụ cáp lâu và đa dạng tùy chọn về lắp đặt Phiên bản chuẩn hóa cho các mô hình Medium Series 305 được các Kỹ sư cơ khí trên toàn thế giới đều tin dùng vào sản phẩm này.

Mô tả

Brevetti cable chain được thiết kế để đáp ứng bất kỳ yêu cầu bảo vệ sự hoạt động của dây cáp và ống thủy lực. Dây chuyền của chúng tôi có thể chịu được các ứng dụng nặng nhất. Một danh sách về các ứng dụng có thể cho dây chuyền của chúng tôi bao gồm các chiều ngang và dọc, khoảng cách di chuyển dài hơn 400 m, các ứng dụng có vỏ bọc bảo vệ, vòng quay trên đường kính từ dưới 1 m đến trên 30 m, robot. Xem qua danh sách kích thước trong biểu đồ dưới đây để xác định chuỗi phù hợp nhất với ứng dụng của bạn.

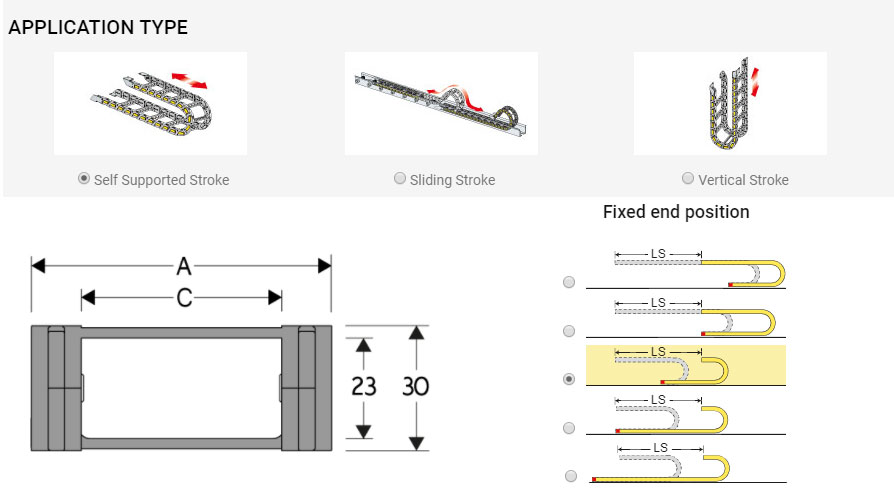

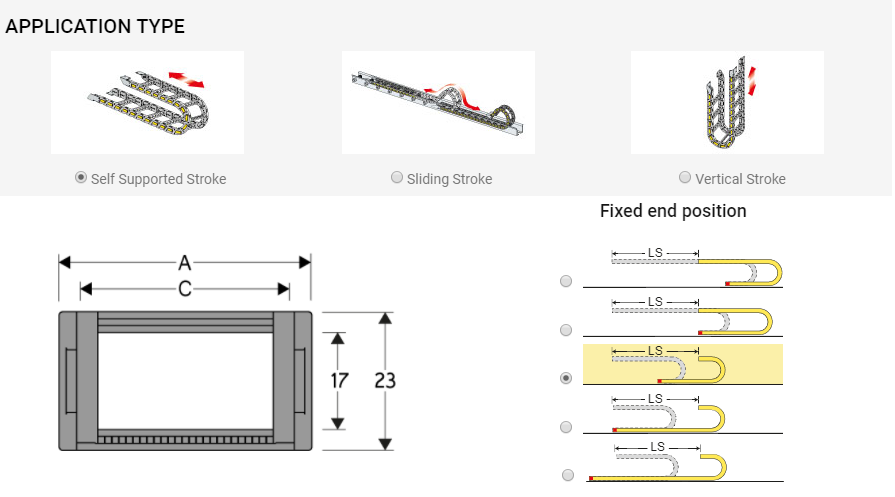

| Inner width | inner height | Outer width | Outer height | Pitch | Bend Radius | Weight |

| 30 mm | 23 mm | 54 mm | 30 mm | 35 mm | 50.70.120.150 | 0.9 kg |

| 50 mm | 23 mm | 74 mm | 30 mm | 35 mm | 50.70.120.150 | 1 kg |

PERFORMANCES

Temperature range: -30°C + 125°C

HORIZONTAL SELF SUPPORTED STROKE:

Speed: 10 m/s

Acceleration: 50 m/s2

X = Self supported Maximum length (m)

Y = Added weight (kg/m)

SLIDING STROKE:

Speed: 3 m/s

Acceleration: 10 m/s2

VERTICAL STROKE:

Speed: 10 m/s

Acceleration: 50 m/s2

SEPARATORS

SEPARATION SYSTEM

Inner vertical separator

Vertical Separator

The vertical separator must be used to manage the inner space and set the proper space for each cable. Standard mounting every second pitch.

End Bracket

NYLON END BRACKET SET

Nylon end bracket set completes both chian ends and allows for fastening on the outer radius, inner radius, and bulkhead without specifying mounting position.

End brackets set for 305009

STEEL END BRACKET SET

Nylon end bracket set completes both ends of the chain and allow for fastening on inner and outer radius.

End brackets set for 305009

GUIDE CHANNELS

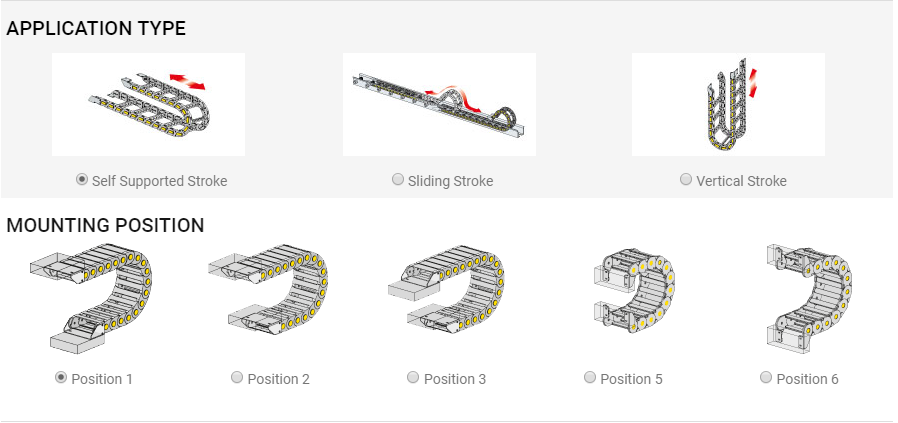

APPLICATION TYPE

Self Supported Stroke

MATERIAL

GROUND CHANNEL

For the correct functioning, the chain must lay on a flat surface. For this purpose ground channels have to be insalled on chain runway. Standard length from 100 mm to 2000mm, at multiple of 100mm. Upon request length up to 3000 mm can be delivered. In following fields please fill the requested sector length and the sector quantity needed.

A5 = 76 mm; H = 20 mm; S = 1.5 mm;

Gude channel for chain 305009

Sliding Stroke

GUIDE CHANNEL

SINGLE CHAIN APPLICATION

DOUBLE OPPOSITE CHAIN APPLICATION

MATERIAL

OPEN GUIDE CHANNEL

Open guide channels must be used in all sliding applications. They must be installed on radius runway and are availabe in standard length of 2m. Ordering example for 4 meter channel: 4 sidewalls, 4(+1) joining and support sets and if present 4(+1) base profiles.

A1 = 78 mm; A2 = 161 mm; H1 = 30 mm; H2 = 96.5 mm; S = 1.5 mm;

Gude channel for chain 305009

GUIDE CHANNELS WITH STEEL ANGLE PLATE

Guide channels with steel angle plate must be used in all sliding applications on the opposite radius runway. Availabe in standard length of 2m. Ordering example for 4 meter channel: 4 sidewalls, 4 angle plate sets, 4(+1) joining and support sets and if present 4(+1) base profiles .

A1 = 78 mm; A2 = 161 mm; H1 = 30 mm; H2 = 96.5 mm; S = 1.5 mm;

Gude channel for chain 305009

Vertical Stroke

MATERIAL

GROUND CHANNEL

For the correct functioning, the chain must lay on a flat surface. For this purpose ground channels have to be insalled on chain runway. Standard length from 100 mm to 2000mm, at multiple of 100mm. Upon request length up to 3000 mm can be delivered. In following fields please fill the requested sector length and the sector quantity needed.

A5 = 76 mm; H = 20 mm; S = 1.5 mm;

Gude channel for chain 305009

MATERIALS

BRYLON 6 TECHNICAL DATA

| Norms | Properties | Units | Dry | Conditioned |

|---|---|---|---|---|

| TERMICHE | ||||

| DSC | Melting point (10° C/min.) | °C | ||

| ASTM – D 696 | Coefficient of linear thermal expansion | X10-6 K-1 | ||

| ASTM D 648 ISO 75 DIN 53461 |

Heat distortion temperature ISO 75 1.82 N/mm2 °C 210 DIN 53461 0.45 N/mm2 |

°C °C |

210 220 |

|

| U. L. 94 | Flammability | H.B. | ||

| IEC 695-2-1 | Incandescent wire Temperature °C 650 Thickness |

650 3 |

||

| FLAMMABILITY | ||||

| ASTM-D 257 | Volume resistivity | Ohm cm | 1015 | 1011 |

| ASTM-D 257 | Surface resistivity | Ohm | 1013 | 1011 |

| ASTM-D 149 | Dielectric strength | KV/mm | 22 | |

| ASTM-D 150 | Dielectric constant (10 Hz) | – | 3.8 | 4.5 |

| ASTM-D 150 | Dissipation factor (10Hz) | – | 0.02 | 0.09 |

| PHYSICAL PROPERTIES |

||||

| ASTM-D 792 | Density | g/cm3 | 1.38 | |

| ASTM-D 570 | Water absorption at 23°C in water for 24 hours | % | 0.90 | |

| MECHANICAL PROPERTIES | ||||

| ASTM-D 638 ISO R/527 DIN 53455 |

Tensile yield stress

Ultimate elongation |

N/mm2

% |

195

2.6 |

115

4 |

| ASTM-D 638 ISO R/527 DIN 53457 |

Tensile modulus of elasticity | N/mm2 | 10600 | 6900 |

| ASTM-D 790 ISO 178 DIN 53452 |

Flexural strength | N/mm2 | 310 | 190 |

| ASTM-D 790 ISO 178 |

Flexural modulus | N/mm2 | 10500 | 6800 |

| ASTM-D 256 | Unnotched Izod impact strength | J/m | 140 | 300 |

| ISO 180/4C | Notched Izod impact strength | KJ/m2 | 110 | 125 |

| ASTM-D 785 | Rockwell hardness | Scala R | 122 | 114 |

CHEMICAL RESISTANCE

| BRYLON 6 | BRYLON 6 | STEEL | ||

|---|---|---|---|---|

| Chemical agents | Concentration % | Amorphous | Crystal | |

| Methyl acetate | 100 | RB3 | RB2 | RB |

| Acetone | 100 | RB4 | RB | RB |

| Acetic acid (aqueous solution) | 40 | AF | AF | AF |

| Acetic acid (aqueous solution) | 10 | AF | AF | AF |

| Acetic acid | AF | AF | AF | |

| Citric acid | 10 | AD 15 | RD | AD |

| Hydrochloric acid (aqueous solution) | 36 | S | S | S |

| Hydrochloric acid (aqueous solution) | 10 | AF | AF | S |

| Hydrochloric acid (aqueous solution) | 2 | AF | AD | S |

| Chromic acid (aqueous solution) | 10 | AF | AF | AF |

| Chromic acid (aqueous solution) | 1 | RD | RD | AF |

| Hydrofluoric acid | 40 | AF | AF | S |

| Formic acid (aqueous solution) | 85 S | S | AD | |

| Formic acid (aqueous solution) | 40 S | AF | AF | AD |

| Phosphoric acid (aqueous solution) | 10 | AF | AF | S |

| Oleic acid | 100 | RB3 | RB3 | RD |

| Sulphuric acid | 98 | S | S | S |

| Sulphuric acid (aqueous solution) | 40 | AF | AF | S |

| Sulphuric acid (aqueous solution) | 10 | AF | AF | S |

| Sulphuric acid (aqueous solution) | 2 | AF | AD | S |

| Tartaric acid (aqueous solution) | RD | RB | RD | |

| Water | RB10 | RB9 | RD | |

| Chlorine water | RD | RD | AD | |

| Ethyl alcohol | 96 | RD17 | RB3 | RB |

| Ammonia | 10 | RB11 | RB | AF |

| Petrol | 100 | RB1 | RB | RB |

| Bitumen | RD | RD | RB | |

| Potassium carbonate | 100 | RB | RB | AF |

| Sodium carbonate | 10 | RB10 | RB3 | AF |

| Ammonium chloride (aqueous solution) | 10 | RB | RB | AF |

| Calcium chloride (aqueous solution) | 20 | S | S | AF |

| Calcium chloride (aqueous solution) | 10 | RB | RB | AF |

| Sodium chloride | 10 | RB | RB | AF |

| Formaldehyde (aqueous solution) | 30 | RD | RB | AD |

| Fat | RB | RB | RB | |

| Milk | RB | RB | RB | |

| Mercury | RB | RB | RB | |

| Oils | RB | RB | RB | |

| Oil | RB | RB | RB | |

| Paraffin oil | RB | RB | RB | |

| Silicon oil | RB | RB | RB | |

| Diesel oil | RB | RB | RB | |

| Mineral oil | RB | RB | RB | |

| Ozone | AF | AF | AF | |

| Oil | RB | RB | RB | |

| Potassium hydroxide (aqueous solution) | 10 | RB9 | RB3 | S |

| Sodium hydroxide (aqueous solution) | 50 | RD | RD | S |

| Sodium hydroxide (aqueous solution) | 10 | RB5 | RB | S |

| Sodium hydroxide (aqueous solution) | 5 | RB9 | RB | S |

| Aluminium sulphate | 10 | RB | RB | AF |

| Soap (aqueous solution) | RB | RB | RB | |

| Tincture of iodine | AF | AF | AD | |

| Trichloroethylene | RD5 | RD4 | RB | |

| Vaseline | RB | RB | RB |

Legend

The table shows the resistance to chemical agents of BRYLON 6 and Steel. The number by resistance value side shows which is the % weight increase due to swelling.

RB – Very good resistance.

RD – Good resistance.

AD – Limited resistance.

AF – Poor resistance.

S – Soluble.

Amorphous – Polymer in amorphous state.

Crystal – Polymer in crystalline state.